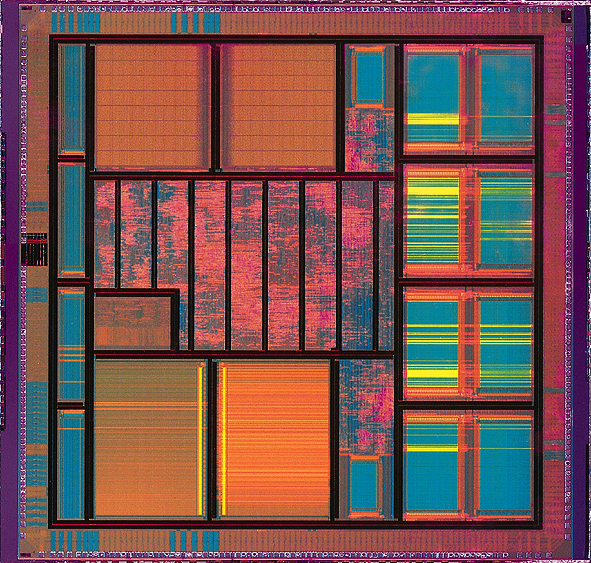

Modern manufacturing methods are spectacularly inefficient in their use of energy and materials. Overall new manufacturing systems are anywhere from 1,000 to 1 million times bigger consumers of energy, per pound of output, than traditional industries. Microchips use orders of magnitude more energy than manhole covers.

This according to a detailed MIT analysis of 20 major manufacturing processes. “The seemingly extravagant use of materials and energy resources by many newer manufacturing processes is alarming and needs to be addressed alongside claims of improved sustainability from products manufactured by these means,” says Timothy Gutowski [pdf] of MIT’s Department of Mechanical Engineering.

Manufacturers have traditionally been more concerned with price, quality, or cycle time, and not as concerned with energy use. That will change, though, when energy prices rise again and when/if a carbon tax is adopted.

Take solar panels. (Say it isn’t so!) Their production uses some of the same manufacturing processes as microchips but on a larger scale. Plus their production is escalating dramatically. The inefficiency of current solar panel manufacturing drastically reduces the technology’s lifecycle energy balance.

Translation: the ratio of energy the panel produces over its useful lifespan compared to the energy required to manufacture it sucks.

The good news is that this study published in Environmental Science & Technology is making the first important steps toward understanding which processes are most inefficient and which and need further research to develop less energy-intensive alternatives.

Example: many newer processes involve vapor-phase processing (e.g., material is vaporized in a vacuum chamber to make a coating). Depositing a coating from a liquid solution is better and could be developed to downsize the energy footprint.

The study covered everything from old fashioned industries like a cast-iron foundry all the way up to semiconductors and nanomaterials. It included injection molding, sputtering, carbon nanofiber production and dry etching, along with more traditional machining, milling, drilling and melting. (However, the researchers only looked at processes where electricity was the primary energy source, hence no analysis of pharmaceutical or petroleum industries.)

Plus the figures are inherently conservative since they don’t include things like the energy required to make the materials themselves or the energy required to maintain the environment of the plant (air conditioning, filtration).

Gutowski’s bottom line: new processes are huge users of materials and energy and have increased our energy and materials consumption by three to six orders of magnitude. The “claims that these technologies are going to save us in some way need closer scrutiny. There’s a significant energy cost involved here [and] each of these processes could be improved.”

Take heed bright green environmentalists.